30 Degree Blades vs. 45 Degree Blades

Which Is Better for Vinyl Wrapping: 30 Degree Blades vs. 45 Degree Blades

Vinyl wrapping has become one of the most popular ways to customize cars, furniture, laptops, and countless other surfaces. Unlike traditional painting, vinyl offers flexibility, reversibility, and creative freedom. But behind every flawless vinyl wrap job is a tool that often goes unnoticed: the cutting blade. If you’ve ever struggled with jagged edges, rough cuts, or vinyl that just won’t sit right, chances are the problem wasn’t your wrapping technique; it was your blade.

Cutting vinyl is not just about slicing through material; it’s about achieving razor-sharp precision without tearing, stretching, or ruining the adhesive backing. That’s where 30 degree and 45 degree blades come in. Each blade angle is designed for specific tasks, and using the wrong one can turn a professional job into a frustrating mess. Think of them like different paintbrushes, sure, you can use one brush for everything, but you’ll never get the perfect finish.

Why Precision Matters in Vinyl Wrapping

Imagine you’re working on a car hood wrap. The curves and edges require clean cuts that hug the contours without lifting or peeling. If your blade drags instead of slicing, you’ll end up with jagged lines that ruin the look. Precision is everything in vinyl wrapping because the material itself highlights even the smallest mistakes.

A sharp, well-chosen blade ensures:

Smooth edges with no fraying.

Minimal adhesive damage.

Easier application and repositioning.

A professional finish that lasts longer.

This is why seasoned wrappers never treat blades as an afterthought. Instead, they select the right blade angle, 30° or 45°, depending on the type of cut needed.

The Role of Cutting Blades in a Perfect Finish

The blade isn’t just a tool; it’s the bridge between your vision and the finished product. Even the best vinyl wrap materials can look cheap if cut poorly. That’s why choosing the correct blade isn’t optional; it’s essential.

30 degree blades are like scalpels, ideal for delicate detail work.

45 degree blades are like utility knives, versatile, strong, and capable of handling most tasks.

Knowing when to switch between them is what separates amateurs from professionals.

What is a 30 Degree Knife Blade?

When people hear “30 degree knife,” they often assume it’s just another cutting blade. In reality, the 30° blade is a precision instrument designed for specialized use in vinyl wrapping and graphic work. Its sharp, acute angle makes it capable of handling intricate cuts that would be impossible with a standard blade.

A 30 degree knife blade is a cutting tool with a sharper angle than the standard 45°. This steep angle makes the blade tip finer and more precise, perfect for cutting small details in thin vinyl films. Think of it as the surgeon’s scalpel of the vinyl world; it’s not about brute force; it’s about accuracy.

Check out our precision 30-Degree NT Blades designed for detailed vinyl cuts →

Key Features and Specifications of 30 Degree Blades

Angle: 30° tip for extra-sharp precision.

Blade Length: Usually shorter cutting depth compared to 45°.

Best Suited For: Thin vinyl films, decals, fine lettering.

Performance: Extremely sharp but less durable for heavy cuts.

Because of its fine tip, a 30° blade doesn’t last as long when cutting thicker or abrasive materials. It’s designed specifically for detail, not durability.

Common Applications of 30 Degree Blades in Vinyl Work

A 30° knife shines in situations where detail is king:

Cutting small vinyl decals.

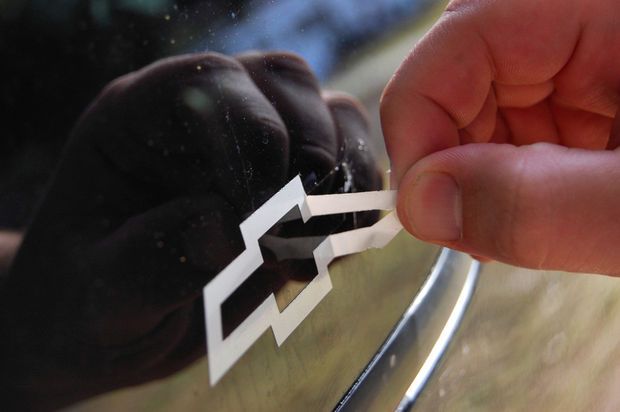

Precision trimming around logos and emblems.

Creating intricate designs with sharp corners.

Working with thin cast vinyl used in car wraps.

If your project demands accuracy over strength, the 30 degree blade is the tool you need. Many professionals keep one specifically for detail work, switching back to a 45° for general cutting.

30 Degree Knife: Why Professionals Use It for Fine Detail Work

Among vinyl professionals, the 30 degree knife has earned a reputation as the blade of choice for precision work. While the 45° blade is great for everyday use, the 30° blade shines when projects demand microscopic detail.

Advantages Over Other Blades in Precision Cutting

The acute angle of the 30° blade makes it ideal for:

Sharp corners – Perfect for lettering with narrow strokes.

Intricate patterns – Handles swirls, curves, and fine lines effortlessly.

Small decals – Ensures no lifting or tearing in tiny designs.

Because of its sharper point, it slices through vinyl like butter without dragging or stretching the material. For projects where every millimeter counts, nothing beats a 30°.

Real-World Examples of Detailed Vinyl Wraps

A business logo with tiny lettering that still looks sharp from up close.

Custom pinstripes on cars, cut to razor-thin accuracy.

Laptop skins with intricate mandala patterns.

Wall decals with complex shapes and curves.

For professionals, having a 30° knife on hand is like having a fine-tip pen next to a marker; you won’t use it for everything, but when detail matters, nothing else compares.

What is a 45 Degree Knife Blade?

Now let’s talk about the 45° blade, the workhorse of vinyl wrapping. If the 30° blade is a scalpel, the 45° blade is a chef’s knife: versatile, strong, and capable of handling almost everything you throw at it.

A 45 degree knife blade is the most common type of cutting blade used in vinyl applications. It has a slightly wider angle than a 30° blade, making it more durable and suitable for a wider range of materials.

For thicker films and stronger cuts, explore our 45-Degree NT Blades →

Key Features and Specifications of 45 Degree Blades

Angle: 45° tip for balanced sharpness and durability.

Blade Length: Deeper cutting capacity than 30°.

Best Suited For: Standard vinyl wrapping, thicker films, and everyday use.

Performance: Highly versatile, longer-lasting, ideal for most users.

Because of its balance between precision and strength, it’s the default choice for most vinyl cutters and plotters.

Common Applications of 45 Degree Blades in Vinyl Wrapping

A 45° blade is the go-to option for:

Cutting standard vinyl wraps.

Handling thicker calendared vinyl films.

Every day trimming and application.

Beginners learning the basics of vinyl wrapping.

In short, if you can only have one blade in your toolkit, make it a 45°. It covers 90% of your vinyl cutting needs.

45 Degree Knife: The All-Purpose Workhorse

If the 30 degree knife is the scalpel, the 45 degree blade is the Swiss Army knife of vinyl wrapping. It’s the most widely used blade angle for one reason: it does just about everything well. Whether you’re a hobbyist starting out or a seasoned installer tackling full car wraps, the 45° blade is the tool you’ll reach for the most.

Why It’s a Must-Have in Every Toolkit

The 45° blade offers the perfect balance of precision and strength. It’s sharp enough to handle detailed cuts for medium-sized designs, yet durable enough to cut through standard vinyl films without wearing out quickly. This makes it the go-to choice for everyday work.

Key benefits include:

Versatility – Works well with cast vinyl, calendared vinyl, and even heat transfer vinyl.

Durability – Holds its edge longer compared to 30° blades.

Ease of use – Beginners can rely on it without worrying about snapping the tip or ruining delicate cuts.

Unlike the 30° blade, which specializes in fine details, the 45° blade is designed for broad use. If you could only keep one blade in your kit, this would be it.

When to Use It Instead of a 30 Degree Blade

There are many situations where the 45° blade outperforms the 30°:

Large vinyl wraps – covering car hoods, doors, or panels.

Thicker calendared vinyl – where a 30° blade might snap or dull quickly.

General trimming – around windows, bumpers, or straight edges.

Beginners’ projects – learning with a forgiving, all-purpose blade.

Think of the 45° blade as your reliable daily driver, while the 30° is your specialty tool for delicate jobs. Both are essential, but the 45° is the blade you’ll lean on the most.

30 Degree vs. 45 Degree Blades: A Direct Comparison

Now that we know what each blade does, the big question is: which one should you use for vinyl wrapping? The truth is, both have their place in your toolkit, but their effectiveness depends on the task at hand.

Sharpness and Cutting Angles

30° Blade: Sharper tip, better for detail, struggles with thick vinyl.

45° Blade: Balanced sharpness, works with a wide range of materials.

Durability and Blade Longevity

30° Blade: Wears out quickly if used on thick films.

45° Blade: Lasts longer, even with heavy use.

Best Use Cases for Each Blade Type

30°: Fine lettering, intricate graphics, precision cuts.

45°: General vinyl wrapping, thicker films, large surface cuts.

Which Blade is Better for Beginners vs. Professionals?

Beginners: A 45° blade is easier to handle and more forgiving.

Professionals: A 30° blade is a must-have for detail work.

The real secret? Most professionals use both. They keep a 45° blade as their everyday cutter and switch to a 30° when the job demands detail.

How to Choose the Right Blade for Your Vinyl Project

Selecting the right blade isn’t about picking the “better” one; it’s about choosing the right tool for the job.

Factors to Consider Before Buying

Vinyl Thickness: Thin films need sharper blades.

Project Type: Detailed designs require precision, while full wraps need durability.

Skill Level: Beginners should start with versatile blades before advancing.

Matching Blade Types to Vinyl Thickness

Thin Cast Vinyl: 30° blade.

Standard/Calendared Vinyl: 45° blade.

Specialty Materials (reflective, textured): 60° blade (beyond the scope here but worth noting).

Cost vs. Performance Considerations

While 30° blades might cost a little more per replacement due to wear, they’re invaluable for detail work. A 45° blade gives you the best long-term value since it handles most tasks without frequent replacement.

The smart move? Invest in both blade types so you’re prepared for any project.

Browse our full Knife, Cutters & Blades Collection to find the right fit for your projects →

Blade Maintenance and Care Tips

Buying the right blade is only half the story. If you don’t take care of your 30 degree knife or 45 degree blade, you’ll quickly find yourself replacing them more often than you’d like. Proper blade care isn’t just about saving money; it’s about maintaining consistent, professional-quality cuts over time. Think of it like sharpening a chef’s knife: the better you maintain it, the longer it serves you.

Proper Storage Techniques

One of the most common mistakes people make is tossing their blades into a drawer with other tools. This dulls the edge almost immediately. Blades should always be stored in their protective cases or blade holders. If you’re carrying them to job sites, consider investing in a small blade organizer that keeps different angles (30°, 45°, and even 60°) separated and protected.

Storing blades in a dry, clean environment also prevents rust. While most modern blades are stainless steel or carbide-tipped, even the best blades degrade when exposed to moisture or sticky adhesive residue. A small silica gel packet in your storage box can help absorb moisture and keep blades sharp for longer.

Sharpening and Replacement Guidelines

Here’s the reality: vinyl cutting blades don’t last forever. Even the sharpest 30° blade will eventually dull, especially if you’re cutting thick calendared vinyl or reflective films. While sharpening is possible for certain blade types, most vinyl professionals prefer replacing them for consistent results.

Pair your blades with our Vehicle Wrapping Tools Collection for a complete installation setup →

As a general guideline:

30 degree knife blades may need replacing after cutting through 500 to 700 feet of thin cast vinyl.

45 degree blades can last much longer, often 1,000 to 1,500 feet of cutting, before showing signs of dullness.

A simple test is to cut a small decal with fine details. If the vinyl starts tearing, lifting, or requiring more force than usual, it’s time for a replacement.

Common Mistakes That Damage Blades

Many beginners unknowingly ruin their blades by making avoidable errors:

Too much cutting pressure – pressing too hard forces the blade into the backing paper, dulling it faster.

Using the wrong blade for the material – for example, using a 30° blade on thick films instead of a 45°.

Cutting on hard surfaces – always use a cutting mat or soft surface to protect the edge.

Not cleaning adhesive buildup – sticky residue on the blade reduces sharpness and causes rough cuts.

By avoiding these pitfalls, you’ll extend the life of your blades and ensure every cut is as clean as the first.

Keep your blades and tools safe in our Tool Bag Collection →

Safety Tips When Using Cutting Blades

Blades may seem like simple tools, but accidents happen more often than you’d think. A 30° knife, with its razor-sharp tip, can cut through skin just as easily as it slices vinyl. Following a few safety practices ensures you stay productive without risking injury.

Proper Handling Techniques

Always grip your knife firmly, keeping your fingers away from the cutting path. Avoid using excessive force; if you’re pressing too hard, your blade is likely dull or the wrong angle for the job. Replace it instead of forcing it.

When cutting freehand, move the vinyl rather than twisting your wrist into awkward angles. This keeps the blade steady and reduces the chance of slipping.

Protective Gear and Workspace Setup

Cutting mats – Prevent blades from slipping and protect your work surface.

Gloves – Cut-resistant gloves add an extra layer of protection when trimming near edges.

Well-lit workspace – Shadows can trick your eyes, leading to slips and mistakes.

Check out Avery Dennison’s wrap tips for achieving smooth, professional finishes →

Also, never leave blades exposed on your desk. Always retract or cover them before setting them down. This prevents accidental cuts and extends blade life by avoiding unnecessary contact.

FAQs

Can I use a 30 degree knife for all my vinyl cutting needs?

Technically yes, but it’s not recommended. A 30° blade is excellent for details but struggles with thicker vinyl and wears out faster. For everyday work, a 45° blade is a better choice.

How do I know when my blade needs replacing?

If your vinyl starts tearing, lifting, or requiring more pressure to cut, your blade is dull. A sharp blade should cut cleanly through vinyl without damaging the backing paper.

What’s the difference between a 30°, 45°, and 60° blade?

30° blade: Best for fine details and thin vinyl.

45° blade: General-purpose, works on most vinyl.

60° blade: Best for thick, specialty, or reflective materials.

Are name-brand blades better than generic ones?

Not always. While brands are reliable, many generic carbide blades perform well if purchased from trusted sellers. Test a few to see what works best for you.

Which blade should beginners start with?

A 45° blade is the best starting point. It’s versatile, forgiving, and covers most vinyl wrapping projects without requiring constant replacements.

Conclusion

When it comes to vinyl wrapping, the debate between 30 degree blades vs. 45 degree blades isn’t about which one is “better”; it’s about which one is right for the job. The 30° blade is your specialist tool for precision and detail, while the 45° blade is the everyday workhorse that gets most tasks done.

For professionals, having both is non-negotiable. A 30° knife ensures razor-sharp detail in intricate designs, while a 45° blade delivers durability and versatility for larger projects. For beginners, starting with a 45° angle is the safest bet, and adding a 30° angle as your skills advance is the smart move.

At the end of the day, investing in the right blades saves you money, time, and frustration, while guaranteeing that every vinyl wrap you complete looks clean, sharp, and professional.

Are you unsure which tool or kit is right for your job?

Our expert team at Oz Sign Supplies is here to help. Reach out today, and we’ll direct you to the best tools to suit your project, ensuring you get the job done right the first time.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.